Injection moulding is frequently a common and hugely efficient producing course of action used to make plastic parts in huge volumes. From everyday things like bottle caps and containers to sophisticated automotive and professional medical parts, injection moulding performs an integral purpose in modern-day creation throughout various industries.

How Injection Moulding Operates

The injection moulding system commences with raw plastic supplies—commonly as pellets—staying fed in a very heated barrel. The material is melted and after that injected right into a metallic mould cavity less than superior stress. The mould, usually comprised of metal or aluminium, is precision-engineered to make the desired form of the product.

Once the molten plastic fills the mould and cools, it solidifies to the final shape. The mould then opens, plus the part is ejected. The cycle then repeats, enabling for large-speed, repeatable producing.

Vital Parts on the System

The mould: The center while in the procedure, this tool decides the design and composition from the remaining element.

The device: Injection moulding equipment are classified by their clamping drive, which will address nearly anything from a few tonnes to various hundred tonnes.

The material: Numerous types of plastics works exceptionally very well, which include ABS, Polypropylene, Nylon, and Polycarbonate, Each and every with particular Attributes fitted to unique applications.

Great things about Injection Moulding

Injection moulding is well-known on account of its a lot of advantages:

Higher efficiency: Once the Preliminary setup is comprehensive, output is very quickly, typically with cycle situations calculated in seconds.

Regularity and read more precision: The method makes sure all is definitely the identical, ideal for higher-quantity production.

Small squander: Excessive plastic are frequently reground and reused, making the procedure much more sustainable.

Style adaptability: Advanced designs, good facts, and completes can all be realized with the right mould layout.

Popular Applications

Injection moulding can be employed in pretty much any industry. In automotive, it helps make inside components and housings. In medical, it produces sterile syringes and containers. In electronics, it’s employed by casings and connectors. The versatility in the system results in it being a significant part of modern day producing.

Conclusion

Injection moulding is often a powerful, Value-effective approach for producing substantial-quality plastic areas. Its pace, scalability, and precision enable it being probably the most chosen choice for brands round the world. Whether or not you’re creating a little gadget or perhaps a intricate industrial part, injection moulding gives trustworthiness and performance at scale.

Judd Nelson Then & Now!

Judd Nelson Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Jaclyn Smith Then & Now!

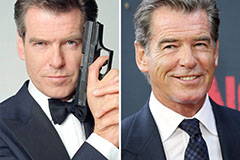

Jaclyn Smith Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!